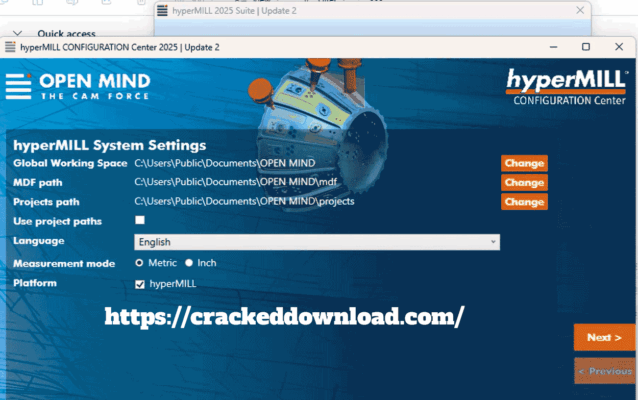

hyperMILL 2025.2 update 2 download with crack license working

email to request:

[email protected]

With the new tessellation algorithm and the new, simplified element display for CAD models, as well as improved algorithms of our 3D strategies, you benefit from noticeably faster working and even more precise processing results.

A highlight of the new hyperMILL release are three innovative strategies for deburring holes and part edges – for maximum flexibility and the highest quality. In addition, the new 5-axis automatic tool orientation mode ensures optimized machining, enabling efficient and reliable tool paths, even for the most complex components.

Benefit: Faster rough machining and improved behavior with large infeeds and rest material.

The optional license “5-axis Deburring” enables the use of both strategies: “5-axis Hole Deburring” and “5-axis Deburring” in 5-axis mode. The 3-axis mode is included as standard in the hyperMILL 3D package.

Benefit: Fast, simple, and safe deburring of holes.

Hypermill 2025 update2 OPEN MIND cracked license unlocked unlimited

Hypermill 2025 update2 OPEN MIND cracked license unlocked unlimited

Benefit: Easy programming of a brushing tool and deburring of holes and other features.

Benefit: Fast and effective deburring of component edges.

Benefit: 5-axis machining of ISO surfaces with increased surface quality and programming support through intelligent algorithms.

email to request:

[email protected]

hyperMILL 2025 full crack download

hyperMILL 2025 offers you even more performance and efficiency, both for CAD and CAM.

hyperMILL CAD/CAM software: What’s new in 2025?

With the new tessellation algorithm and the new, simplified element display for CAD models, as well as improved algorithms of our 3D strategies, you benefit from noticeably faster working and even more precise processing results.

A highlight of the new hyperMILL release are three innovative strategies for deburring holes and part edges – for maximum flexibility and the highest quality. In addition, the new 5-axis automatic tool orientation mode ensures optimized machining, enabling efficient and reliable tool paths, even for the most complex components.

3D Optimized Roughing

The pocket milling algorithm has been redeveloped for the roughing mode of the strategy in order to achieve greater efficiency during roughing and better machining control. A benefit of the new version is realized when machining with large lateral infeeds and remaining material. Additionally, you can define a contour radius and a path radius, allowing you to better control toolpath roundings. The contour radius is used for toolpaths along the model geometry, while the path radius is used for all other offset paths.Benefit: Faster rough machining and improved behavior with large infeeds and rest material.

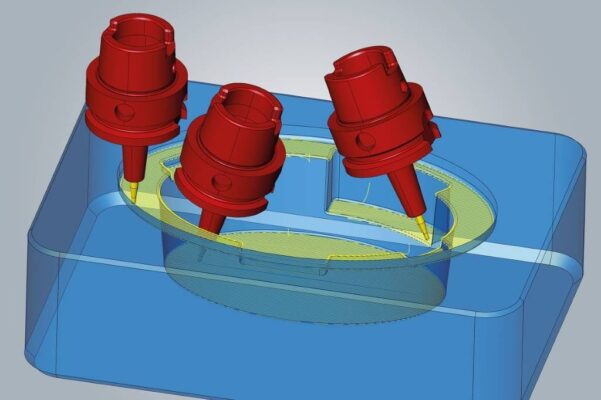

New strategies for precise deburring

Burr-free edges and holes are not only functionally important, but also an essential component of a high-quality end product. With hyperMILL 2025 you have a comprehensive selection of deburring strategies available directly at the machine.

The optional license “5-axis Deburring” enables the use of both strategies: “5-axis Hole Deburring” and “5-axis Deburring” in 5-axis mode. The 3-axis mode is included as standard in the hyperMILL 3D package.

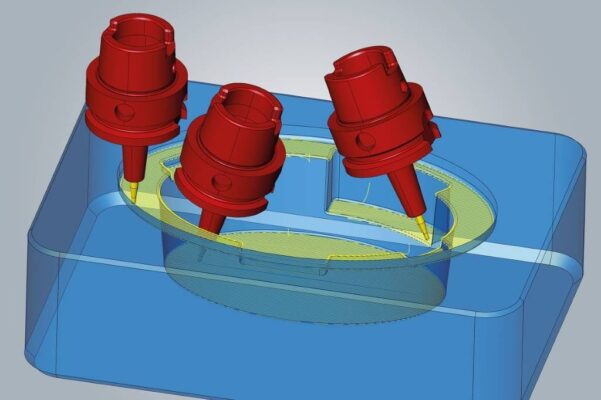

Left | 5-axis Hole Deburring

This new strategy makes it very simple to deburr sharp edges on holes and intersecting holes. Thanks to our intelligent function, the CAM Plan, all holes are automatically recognized, and all sharp edges in the model are marked. You only need to select the desired edges, and the strategy automatically calculates all toolpaths. The strategy supports a 3-axis mode, which is already included in the hyperMILL 3D package, and a 5-axis mode. In the 5-axis mode, machining is indexed where possible. If this is not feasible, it is carried out with 5-axis simultaneous movements.Benefit: Fast, simple, and safe deburring of holes.

Center | Hole Brushing

Use this new strategy to deburr or improve the surface quality of cross holes, threads, or other features with a special brushing tool. The machining process is divided into different phases, and for each phase, machining parameters such as spindle speed, feedrate, coolant, and dwell time can be defined. Under the “Parameters” tab, settings for the machining area, brushing direction, and the number of repetitions can also be made.Benefit: Easy programming of a brushing tool and deburring of holes and other features.

Right | 5-axis Deburring

This new hyperMILL strategy provides you with a fast and effective solution to deburr all sharp edges of a part. You can choose between a 3-axis machining, which is already included in the hyperMILL 3D package, and a 5-axis machining mode. Thanks to the 5-axis option, you can reach more component edges, and the necessary inclinations as well as collision avoidance are generated automatically. The edges are preferably machined with a fixed approach. If this is not possible, simultaneous machining is used. This strategy supports both lollipop and ballmill cutters.Benefit: Fast and effective deburring of component edges.

5-axis ISO Machining

Use our new 5-axis strategy* to machine individual or a few contiguous surfaces according to the course of the ISO lines (U and V). The functions that you are already familiar with from 3D ISO Machining can now also be used for 5-axis machining. In addition to feed adjustment for curvatures and 3D radius correction, the high-precision surface mode can be used with our True-Shape Technology.Benefit: 5-axis machining of ISO surfaces with increased surface quality and programming support through intelligent algorithms.